Igrisi yemisebenzi eminingi ingamboza izinhlelo zokusebenza eziningi ikwenze kufiseleke ekunciphiseni uhlu lwezimpahla nezindleko ezihambisanayo, kanye nokwenza lula uhlelo lokuthambisa.Ngokuvamile, amafutha amaningi e-lithium ajiyile futhi anezithasiselo ze-Antiwear (AW) kanye/noma I-Extreme Pressure (EP) namafutha ayisisekelo anama-viscosity asuka ku-SAE 30 kuya ku-SAE 50.

Kodwa amafutha asetshenziselwa izinto eziningi awakwazi ukuphatha zonke izinhlelo zokusebenza endaweni evamile yezimboni.Ukuze siqonde amafutha, kufanele sibheke ukwakheka kwamafutha.Igrisi empeleni yakhiwe ngezinto ezintathu;isisekelo sesitoko noma amasheya, i-thickener kanye nezithasiselo.

Lapho ucubungula amafutha, izici ezijwayelekile okufanele zicatshangelwe zihlanganisa;

- Uhlobo lwe-Grease Thickener

- Uhlobo lwe-Base Fluid

- I-Base Fluid Viscosity

- Izidingo ezingeziwe

- Ibanga le-NLGI

Futhi cabangela izimo zemvelo zesicelo.Izinga lokushisa elizungezile nendawo yesicelo kuyadingeka ukuze kuhlolwe izimo lapho amafutha kufanele enze khona.Izindawo ezimanzi nezimo ezinothuli zidinga ukuphinda kufakwe kaningi ukuze kusize ukugcina lokhu kungcolisa kungangeni ezingxenyeni.Futhi cabangela izinga lokushisa lokusebenza lohlelo lokusebenza kanye nempahla yokubuyisela kabusha ukuze unqume umkhiqizo ongcono kakhulu ongawusebenzisa kanye nendlela engcono kakhulu yokufaka igrisi.Ukude noma okunzima ukufinyelela kuzo izindawo yenzela okokugcoba okuzenzakalelayo.Kusukela ohlotsheni lwamafutha ayisisekelo kanye nombono we-viscosity, amazinga okushisa okwedlulele kufanele afakwe esinqumweni sokuthi iyiphi igrisi okufanele ikhethwe.

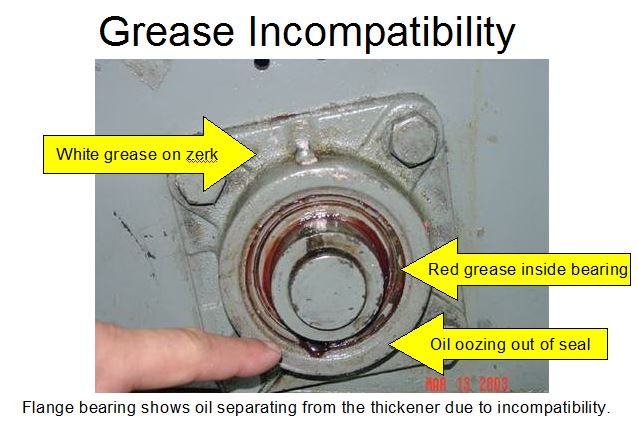

Izithako zamafutha ziningi ngenani kanti ezinye zinezakhiwo nezinzuzo ezihlukile.Ezinye izinhlobo ze-thickener zingangeza izici zokusebenza kugrisi.Isibonelo, ukumelana kwamanzi kungathuthukiswa lapho kusetshenziswa i-aluminium complex noma i-calcium complex thickeners.Kukhona inzuzo yokushisa ukuthi amanye ama-thickeners abe ngaphezu kwamanye.Ukuhambisana kwe-Thickenerikhathaza kakhulu.BanguAmashadi Okuhambelana Kwe-Thickeneretholakalayo ukuze icatshangelwe, kodwa indlela engcono kakhulu ukubonisana nomphakeli wakho ukuze ubone ukuthi baye benza izivivinyo zokusebenzisana ngokumelene nezinhlobo ezahlukene zama-thickener.Uma kungenjalo, ukuhlola ukuhambisana kwegrisi kungenziwa ngamakhulu ambalwa amadola ukuze kuqinisekiswe izinkinga zokuhambisana.

Izitokwe eziyisisekelo ezisetshenziswa kumafutha ngokuvamile zingamafutha amaminerali, ama-synthetic blends noma izitokwe zokwenziwa ezigcwele.Amafutha okwenziwa e-Polyalphaolefin (PAO) asetshenziswa njalo, njengoba lawa ehambisana namafutha esisekelo samaminerali.Olunye uketshezi lokwenziwa olusetshenziswa ekwenziweni kukagrisi luhlanganisa ama-esters, uketshezi lwe-silicone, ama-Perfluoropolyethers, nezinye izinto zokwenziwa nezixube zokwenziwa.Futhi, ukuhambisana kwe

isitokwe esiyisisekelo esisetshenziswa kumafutha ahlukene asiqinisekisiwe.Hlola idatha eyenza amafutha ukuze ubone ukuthi isho uhlobo lukawoyela wesisekelo.Uma kunokungabaza, thintana nomphakeli ukuze uthole ulwazi olwengeziwe ngohlobo loketshezi oluyisisekelo olusetshenziswa kugrisi ikhandidethi.Ihlole ukuthi iyahambisana yini noketshezi oluyisisekelo olusetshenziswa kugrisi esebenzayo njengamanje.Khumbula ukuthiI-viscosity yoketshezi oluyisisekelo olusetshenziswa kugrisi kufanele ifaniswe eduze ngangokunokwenzeka nezimfuneko Zejubane, Lomthwalo kanye Nezinga Lokushisa zohlelo lokusebenza..

Izithasiselo ezifakwe kugrisi ngokuvamile zingama-antioxidants, i-rust and corrosion inhibitors, kanye ne-antiwear noma izithasiselo zokucindezela okukhulu (EP).Izithasiselo ezikhethekile zingadingeka ukuze kwandiswe ukusebenza.Izithambisi ezinamathelayo neziqinile njenge-Molybdenum Disulfide (Moly) zengezwa kugrisi ukuze kuhlinzekwe ukuvikeleka okwengeziwe lapho izimo zidlulele noma ukubuyisela kabusha kunzima ukufeza.

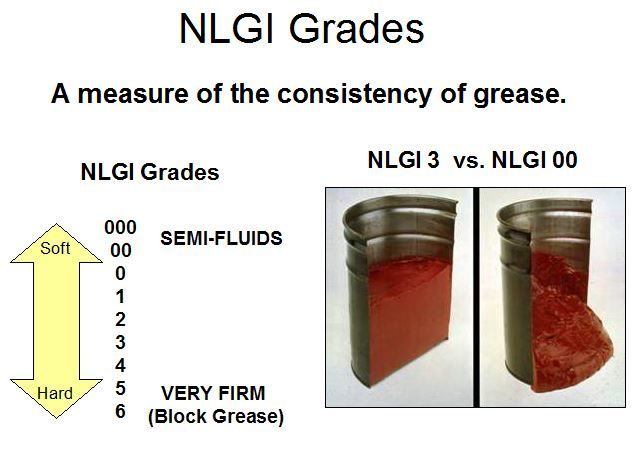

I-National Lubricating Grease Institute (NLGI) Amabanga ayisilinganiso samafuthaukungaguquguquki.Okusho ukuthi ikala ukuqina kwamafutha noma ukuthamba nge-ASTM D 217, ukuhlolwa kwe-"Cone Penetration of Lubricating Grease".Kukhona "amabanga" ahlukene e-NLGI ayisishiyagalolunye ahlanganisa u-000, 00, 0, 1, 2, 3, 4, 5 kanye no-6. Sonke siyawazi amafutha "EP 2".Lokhu kusitshela izinto ezimbili, i-EP 2 grease iyi-NLGI Grade 2 futhi iqiniswa ngezithasiselo ze-Extreme Pressure (EP).Lokhu akusitsheli lutho olunye ngohlobo lwe-thickener, uhlobo lukawoyela wesisekelo noma i-viscosity yamafutha esisekelo.Ibanga elilungile le-NLGI liwukucatshangelwa okubalulekile ngoba akuzona zonke izinhlelo zokusebenza ezifanayo.Okunye ukufakwa kwamafutha kudinga amafutha athambile ukuze akwazi ukumpontshwa kalula ngemigqa emincane yokusabalalisa namavalvu.Ngenkathi ezinye izinto zokugcoba ezifana nama-bearings afakwe ku-shafts mpo zidinga amafutha aqinile ukuze amafutha ahlale ekhona.

Ngazo zonke lezi zici okufanele zicatshangelwe, akumangalisi ukuthi kunokudideka mayelana namafutha.Izikhungo eziningi zezimboni kufanele zikwazi ukusebenzisa idlanzana lamafutha azogcoba indawo yawo ngokuphelele.Kufanele kube khona amafutha aqondene nalokhu:

- Izimoto zikagesi

- High Speed Couplings

- I-Low Speed Couplings

- Izicelo Ezilayishwe Kakhulu/Zejubane Elinensayo

- Izicelo Ezijwayelekile Zokugcoba

Ukwengeza, igrisi eyodwa noma amabili akhethekile angadingeka ekusetshenzisweni ngokweqile.

Amafutha nemishini yokukhipha amafutha kufanele ifakwe umbala futhi ibhalwe ukuze ingaphambanisi imikhiqizo.Sebenza nomphakeli wakho ukuze wazi futhi uqonde amafutha asetshenziswa endaweni yakho.Lapho ukhetha amafutha, zijwayeze ukukhuthala bese ukhetha amafutha afanele wohlelo lokusebenza.

Isikhathi sokuthumela: Dec-28-2020